Anti-condensation greenhouse films cannot stop condensation from developing but they can control the water that does inevitably condense on the surface. With ordinary polyethylene products, water that does condense on the film forms large round droplets, which causes a host of problems for growers that ultimately impact time, crop yield, and cost. Greenhouse condensation control film is designed to have a high affinity for water. Condensed water no longer forms droplets but instead forms a continuous thin sheet of water over the entire film surface moving it away from your valuable crops.

Thermax™ combines outstanding thermal qualities and exceptional condensation control properties in one revolutionary, diffused greenhouse film. The modified outer layer of the anti-condensation greenhouse film safeguards integrity by providing directionality.

This greenhouse film gives you durability, energy savings, plus condensation control

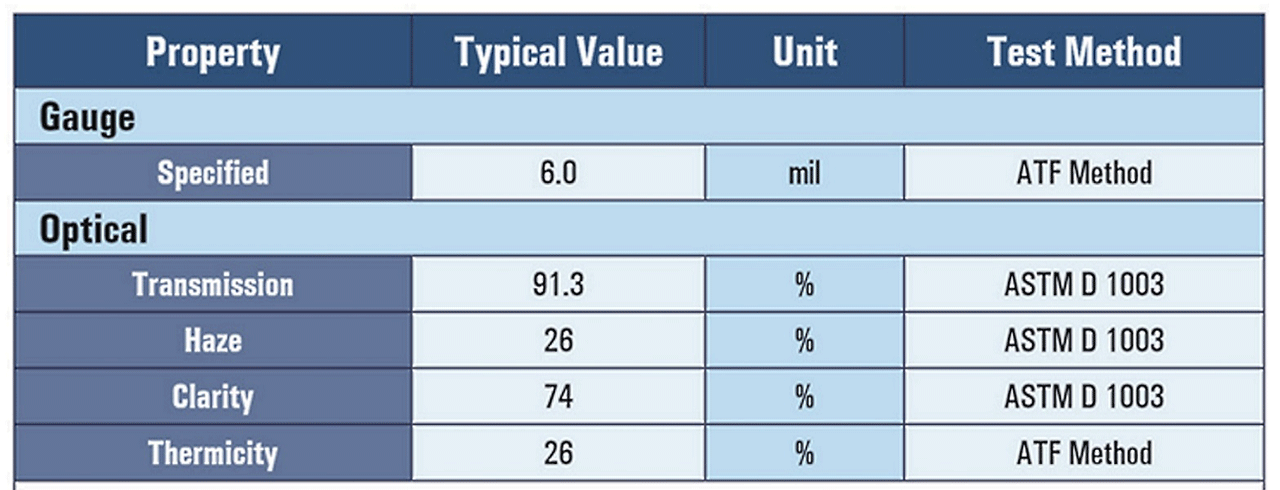

Research shows that a properly inflated double poly-covered greenhouse can save the grower over 40% in heating costs compared to a single layer of glazing. What is less well known is that using a thermal greenhouse film as one of the layers can result in an additional 15-20% heating cost saving. During the day, the greenhouse structure, plants, and soil absorb energy due to both visible and infrared light from the sun. At night, heat is released in the form of long-wavelength infrared radiation (IR) to the cooler outside air. Thermal condensation greenhouse film transmits less IR energy as radiant heat. Thermicity is a measure of the transmission of IR through a film. The lower the thermicity, the lower the transmission of IR and the lower the heat loss. Incorporating an effective condensation control additive into Thermax™ causes condensing water to spread out into a uniform sheet on the interior surface of the thermal greenhouse film. This thin sheet of water is also absorbed in the long-wavelength IR region, meaning it acts as an additional barrier to radiant heat, i.e. enhances thermicity.

Thermax Greenhouse Film Advantages:

- Superior strength handles years of snow and wind loads.

- Water is able to drain more evenly and will flow to the lowest point of the film’s surface.

Light transmission is significantly improved. - Reduces nighttime heat losses, maintains leaf temperatures of the plants, and increases the overall effectiveness of the thermal greenhouse film.

- This greenhouse anti-condensation film features thermal properties that keep the heat in by reducing radiant heat loss. Heaters cycle less often and consume less energy to maintain a set temperature; a combination that offers potential energy savings of 15-20%.

- Directional condensation control ensures the additive migrates to the surface facing the crop. This not only controls drips, but maintains light transmission and enhances thermal benefit.

- Diffused light reaches plants from many different angles while par light transmission remains the same, optimizing light distribution in all parts of the greenhouse.

- Diffusion helps protect plants from sunburn. With Thermax™ greenhouse film, light is even, not intense.

- High strength at the folds of this greenhouse plastic means higher resistance to punctures and tears.

- Increased thermal greenhouse plastic film stiffness makes the film easier to install in greenhouse applications.

- Bee compatibility feature allows more of the UV spectrum to pass through the condensation control greenhouse film, making it easier for bees to navigate and achieve more efficient pollination than with mechanical means.

Formation of condensation on inner surfaces is a major issue in polyethylene-covered greenhouses. Condensation droplets have been shown to reduce light transmission by as much as 50%. In addition, crop damage/spots, washout on seed beds, and possible pathogen development may also occur. Condensation control films contain surface tension modifiers to prevent the formation of these condensation droplets (fogging). The condensation control feature is standard on Thermax™ greenhouse films.

How Condensation Control Greenhouse Film Works

Film with anti-condensation properties does not prevent condensation on the film, but instead controls the water that does inevitably condense on the film surface. Ordinary polyethylene used in greenhouses has no affinity for water. Water that does condense on the film forms round droplets because this shape minimizes the contact between the water and the film. Due to this shape, droplets are only lightly attached to the film and hang loosely. A natural breeze or the vibration from the closing of a greenhouse door can easily make them fall. The shape of the droplet will also reflect light back out of the greenhouse. This loss of light may slow plant growth, delay crop maturity and affect plant yield. The droplets may also act as a lens, focusing sunlight onto the plants, causing burns. A condensation control film is modified to have a high affinity for water. Condensed water no longer forms droplets but instead forms a continuous thin sheet of water over the entire film surface.

It’s important to allow for the normal expansion and contraction of film during installation. Single layer film should be installed snugly, but should not be overly tight. Avoid stretching the thermal greenhouse film during installation. Double poly installations should provide enough slack in the top layer to allow 12” to 24” of inflation.in

NOTE: Condensation control greenhouse films are manufactured with a built-in additive for superior droplet control. To make a condensation control film, the film is modified to have the necessary high affinity for water. This is achieved by incorporating a unique additive into the polymeric matrix of the film during the manufacturing stage. The additive migrates to the film surface to achieve the desired effect. Films with this kind of built-in condensation control eliminate several inherent problems with surface modification techniques used after the film has been produced. For example, the most common post-production surface coating technique for greenhouse and row covers is to use a commercial product called Sunclear (or product equivalent), which is applied like paint by spraying the film after installation. Coating of the condensation film during the manufacturing process is not practical due to the large dimensions of the film, typically 20 to 50 feet wide and 80 to 500 feet long.